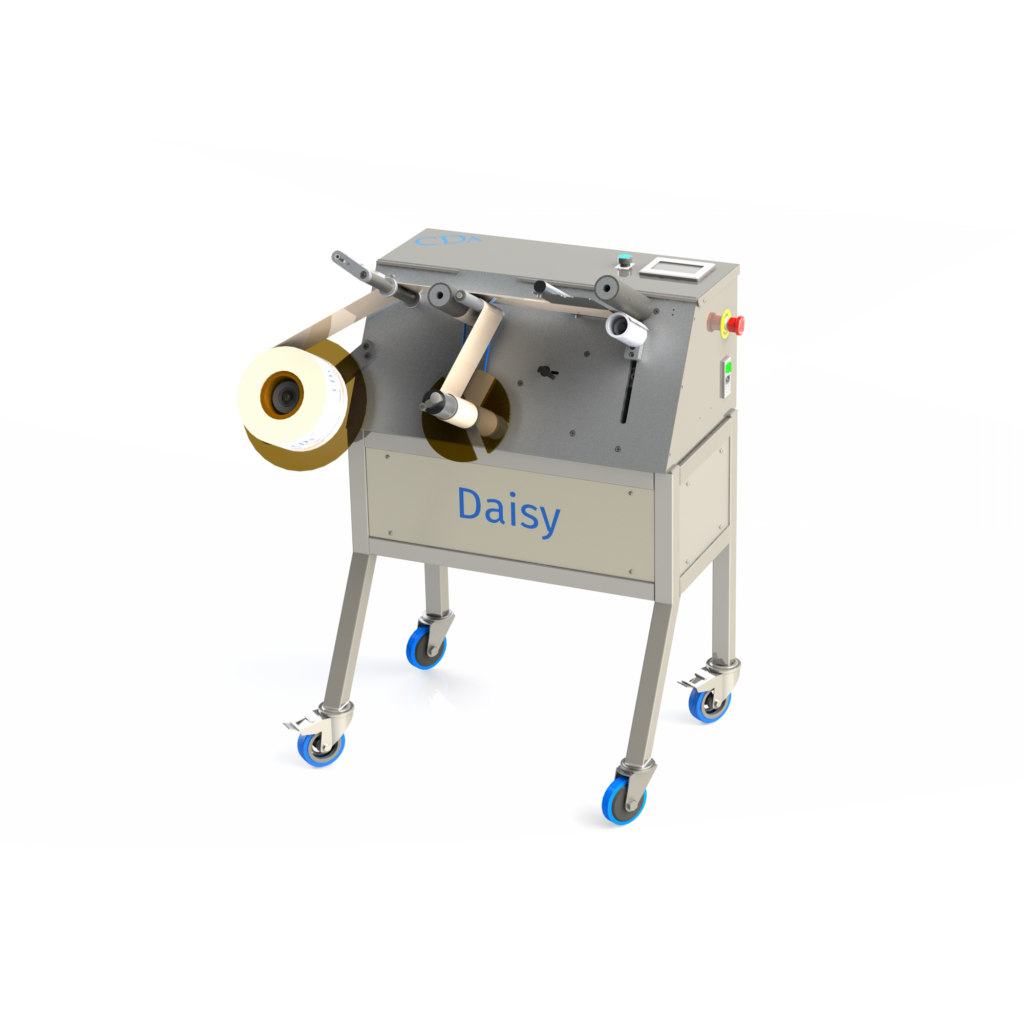

Daisy Label remover for separating adhesive labels from release liner

Daisy is an innovative automatic solution designed to separate self-adhesive labels from their backing for liner recycling. Manufactured by CDA, this machine simplifies the label peeling process.

The operation of the CDA labeller is simple: once the tape has been passed through, a push-button is pressed to start the cycle. The labels are then peeled off from the tape roll and applied to a cylindrical mandrel (chosen by the user), while the liner is wound onto itself. At the end of the process, 2 distinct rolls are created: one formed by the labels stuck together and the second formed by the liner (without labels) wound on itself.

By using our labelling machine, companies can consider recycling this waste (which must absolutely be devoid of labels). Over the past few years, the industry has become more organised, enabling liner to be recycled (to create insulation, for example). Another obvious advantage of the Daisy, is that the machine makes the waste more compact by creating dense rolls for a simplified storage, collection and dispatch. This solution is adaptable and flexible, enabling it to meet a variety of needs (in terms of both the automation and capacity). The Daisy can, for example, be configured as a multi-station machine or fitted with special trays to adapt to different roller sizes.

Thanks to this innovation, our customers can commit more easily, to an eco-friendly approach by working with waste collection companies (such as Re-Use) or liner recycling companies (such as Soprema). This contributes to a more sustainable circular economy, by turning waste into reusable resources.

Container shapes

- Ease of use

- Machine that reduces ecological footprint

-

Tape speedUp to 60 metres/minute

-

StructureStainless steel and aluminium

-

Rotary1 position

Animal products

Candles

Car products

Chemical industry

Food processing industry

Cosmetics industry

Natural products

Paint industry

Parapharmacy

Wine - Spirits

Beer industry

Filling, sealing and labelling machines : learn more about the complete packaging lines.

Whatever your sector of activity or your product, CDA puts the experience of its design office at your disposal to develop and design your complete customised line. CDA offers the packaging line perfectly adapted to your needs by adjusting technologies, dimensions, conveyors, etc.

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labelling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries