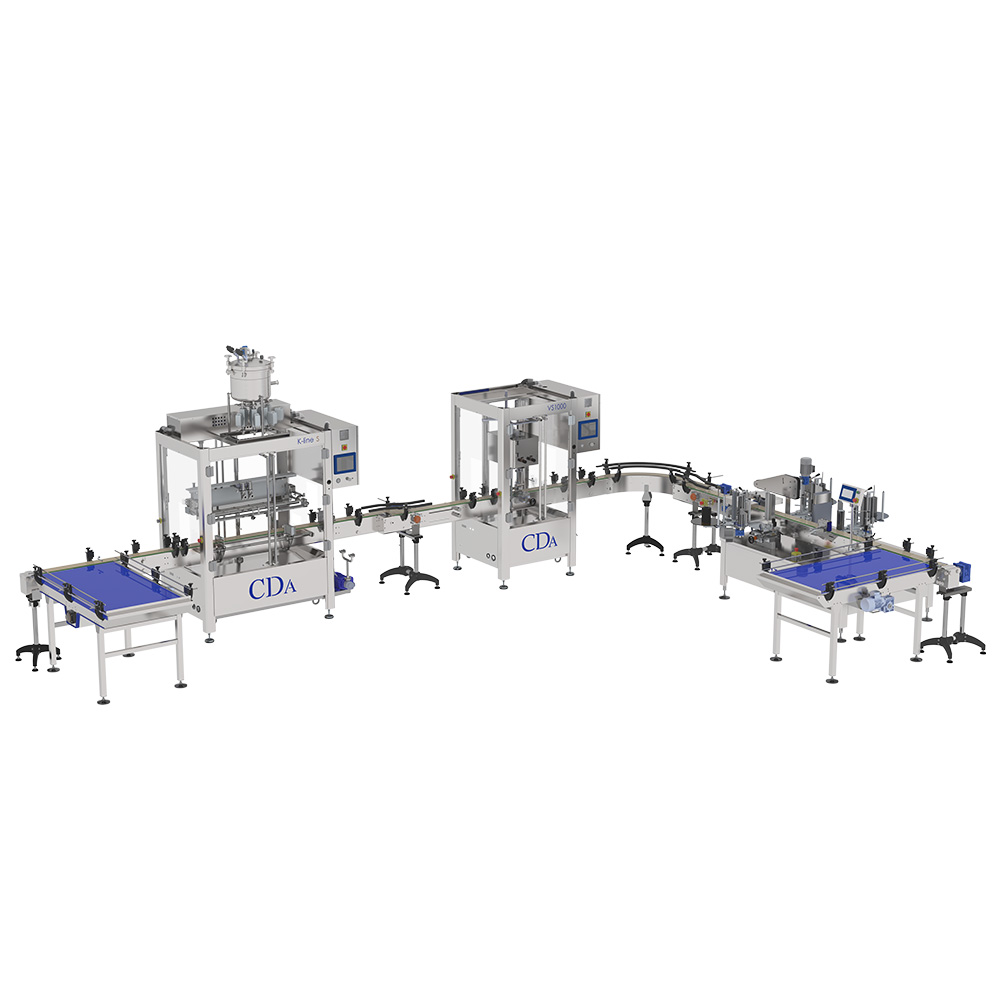

Complete line : K Line S – VS1000 – Ninon Mix K Line S + VS1000 + Ninon Mix

CDA designs turnkey lines combining the 3 essential stages to the packaging of your products; filling, capping and labelling.

The K-Line S is an enclosed linear filling machine. Appreciated for its ease of use and self-cleaning, this filling machine is nonetheless very versatile. Depending on your products, we adapt the appropriate dosing system (volumetric, flowmetric, centrifugal dosing, etc.). The K-Line S can reach 3,000 conditioned liters / hour while maintaining an accuracy of +/- 0.5%.

Tuned by a linear conveyor (or curved depending on your workshop), the VS1000 capper, also fully enclosed, supports a wide variety of caps. Indeed, its capping system operated by electric screwdrivers is ideal for gun caps, spray caps, dropper caps, and many other types of caps.

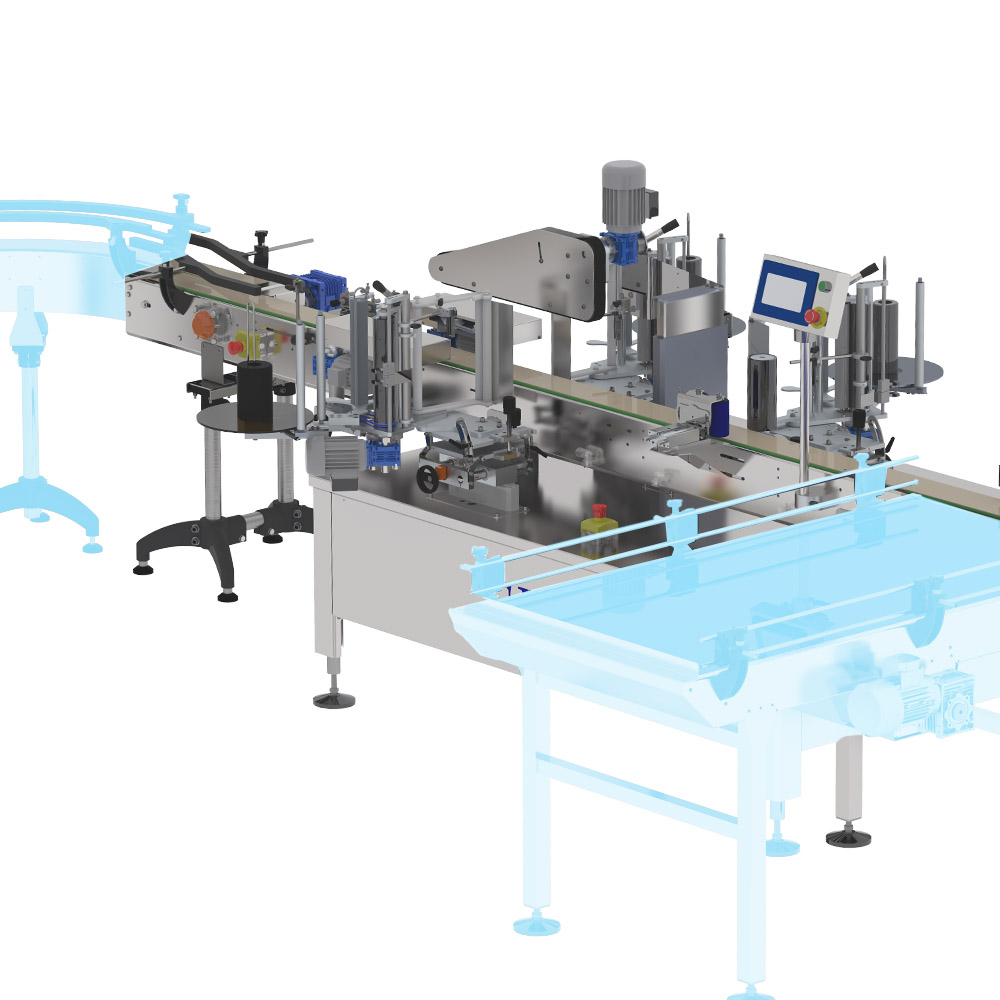

Finally, the Ninon Mix labelling machine finalizes the packaging line. This machine can also, on request, be encased. Very versatile, the Ninon Mix can place labels on cylindrical products, but also tapered, oval or rectangular. Its production rate can reach up to 35 products / minute.

Complementary solutions can be added to complete lines (such as rotary accumulation tables, industrial HSA ink jets or thermal transfer encoders) to give you a solution that is completely adapted to your needs.

Discover all our complete lines on our Youtube channel.

- Up to 35 products/minute

- Versatility : Different dosing and labelling techniques can be integrated to adapt the machine to the range of products to be filled

- Customised layout by our engineering department : Linear, L-shaped, U-shaped packaging line, etc. Infeed table, outfeed table, to adapt to your workshop

-

Labelling rateUp to 35 products/minute

-

Vial sizesFrom 100 ml to 20 litres

-

PumpFlowmeter or piston (depending on viscosity)

Animal products

Car products

Chemical industry

Cosmetics industry

Food processing industry

Natural products

Paint industry

Parapharmacy

Container shapes

Fluid

Heavy

Thick

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries