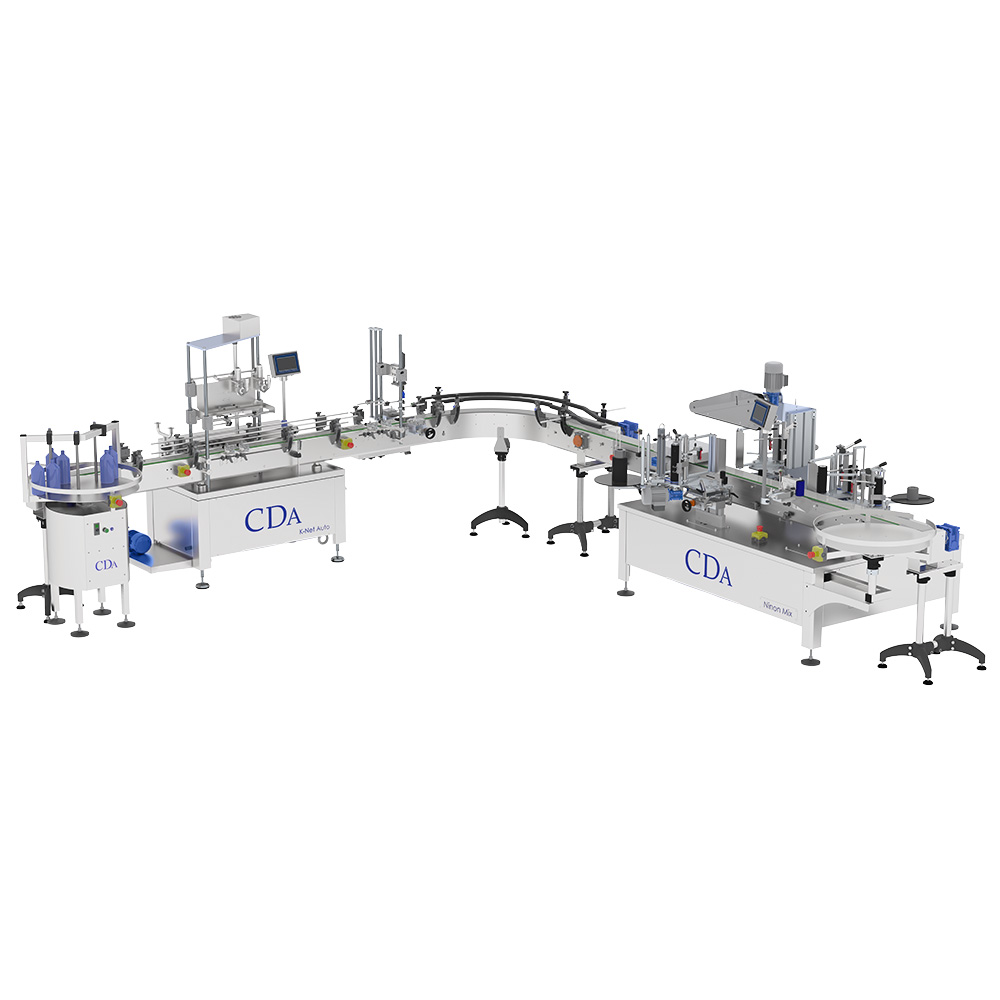

Complete line – K Net Auto – VS400 – Ninon Mix K Net Auto + VS 400 + Ninon Mix

CDA offers the design of complete lines bringing together the 3 key stages of packaging: filling, capping and labelling.

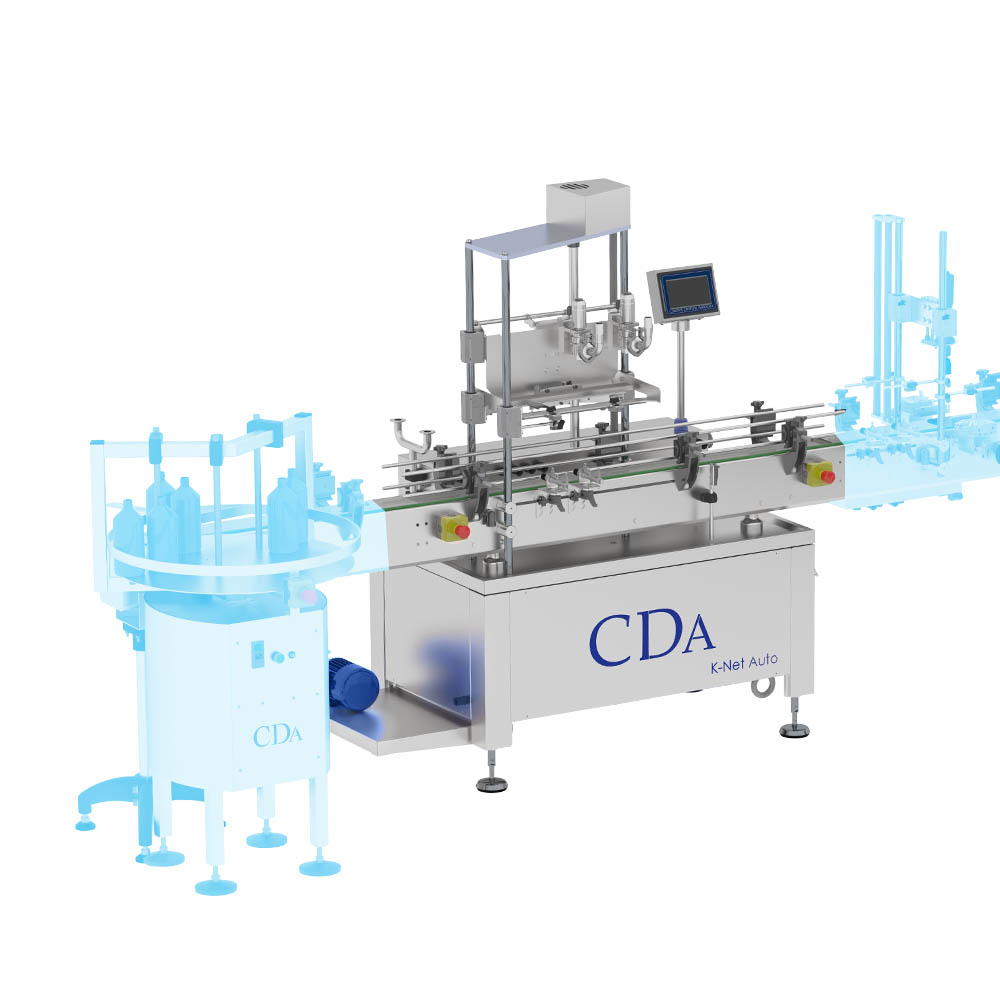

On this line, filling is provided by the K Net Auto, an automatic machine that can fill up to 1,200 products / hour with an accuracy of +/- 0.5% of the dosed liquid. Depending on your industry and your product range, the K Net Auto will be equipped with a suitable dosing system (peristaltic, flowmeter, volumetric, etc.).

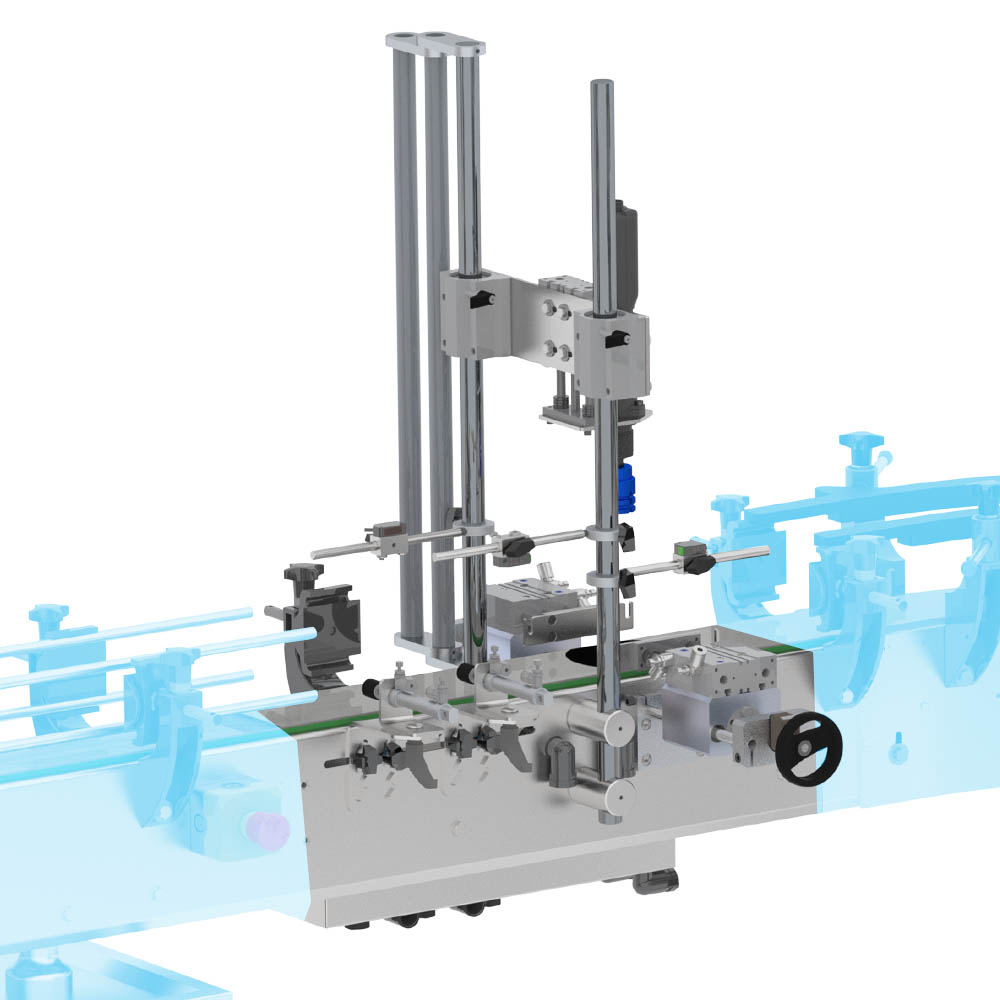

Capping is carried out using the VS 400. This automatic capper is versatile and allows the capping of many cylindrical caps (caps with vertical grooves, dropper caps, pre-threaded screw caps, screw caps, hinged lids, etc. etc.). The operator manually places the cap onto the container which will then be detected and then automatically be capped (tightening torque set via the touch screen) by the capping head.

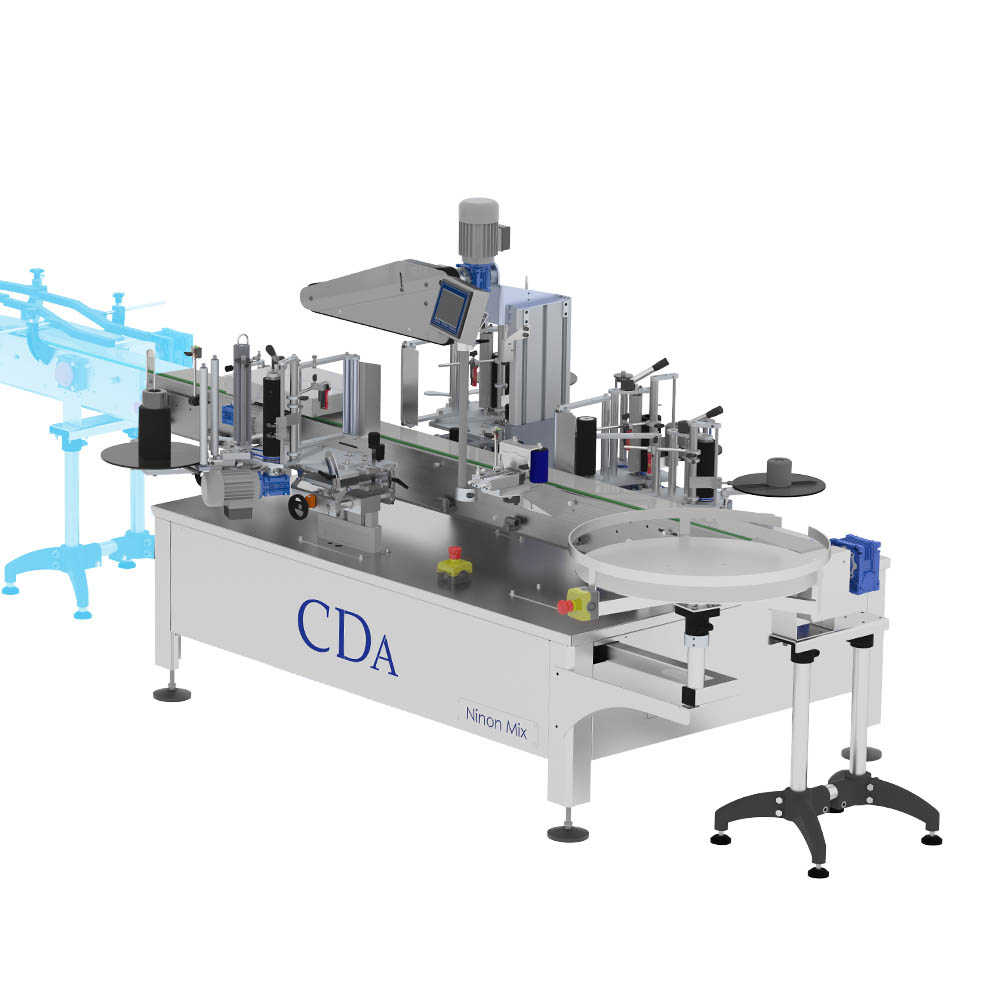

Finally, the labeling is carried out by the Ninon Mix machine. This labeler is one of the most versatile in the CDA range. Square, cylindrical, oval, tapered products … Our labeler covers all of these containers with one to several labels. The production rate of the Ninon Mix can reach up to 20 labeled products / minute.

Complementary solutions can be integrated into your packaging line. Depending on your needs, we install machines transfer, accumulation or marking systems.

Discover all our complete lines on our Youtube channel.

- Up to 20 products/minute

- Versatility : Different dosing and labelling techniques can be integrated to adapt the machine to the range of products to be filled

- Customised layout by our engineering department : Linear, L-shaped, U-shaped packaging line, etc. Infeed table, outfeed table, to adapt to your workshop

-

Labelling rateUp to 20 products/minute

-

Vial sizesFrom 30 ml to 5 litres

-

PumpPeristaltic, flowmeter or piston (depending on viscosity)

Animal products

Car products

Chemical industry

Cosmetics industry

Food processing industry

Natural products

Paint industry

Parapharmacy

Container shapes

Fluid

Heavy

Thick

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries