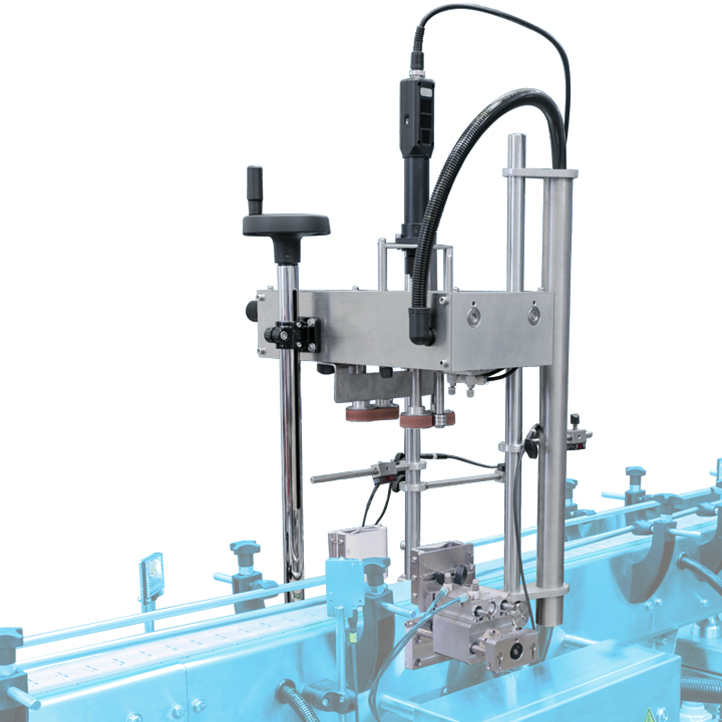

VS 500 Automatic screw capping machine Automatic capping module by screwing for the majority of caps and in particular spray caps or pump caps

The VS500 electric screw capper is a highly efficient automatic capping module that incorporates an integrated screwer, making it the perfect solution for various types of caps, including spray or pump caps. Its versatility allows it to handle different formats with ease, and the crank height adjustment feature ensures optimal performance.

This automatic screw capper is designed to seamlessly integrate into complete filling lines, offering enhanced efficiency and productivity. However, it can also be utilized as a standalone machine outside a complete packaging system, providing flexibility in its application.

Equipped with a 1000mm conveyor, the VS500 can achieve speeds of up to 25 products per minute, depending on the specific format requirements. This makes it suitable for a wide range of production demands.

The VS500 is compatible with CDA’s automatic filling machines such as the K-NET Auto, a linear filling machine capable of handling up to 1200 bottles per hour, and the K-LINE S, a high-capacity linear filling machine with a capacity of up to 3000 litres per hour. It is also compatible with all of CDA’s automatic labelling machines.

For a visual demonstration of the VS500 and to learn more about its features and capabilities, we invite you to explore our YouTube channel.

Cap / Capsule forms

- 500mm conveyor belt

- Ease of use

- Screwing by pump and gun plugs

-

Screwing1 integrated capper

-

Production rateUp to 25 products/minute

Chemical industry

Cosmetics industry

E-liquids

Food processing industry

Paint industry

Filling, sealing and labelling machines : learn more about the complete packaging lines.

Whatever your sector of activity or your product, CDA puts the experience of its design office at your disposal to develop and design your complete customised line. CDA offers the packaging line perfectly adapted to your needs by adjusting technologies, dimensions, conveyors, etc.

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labelling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries