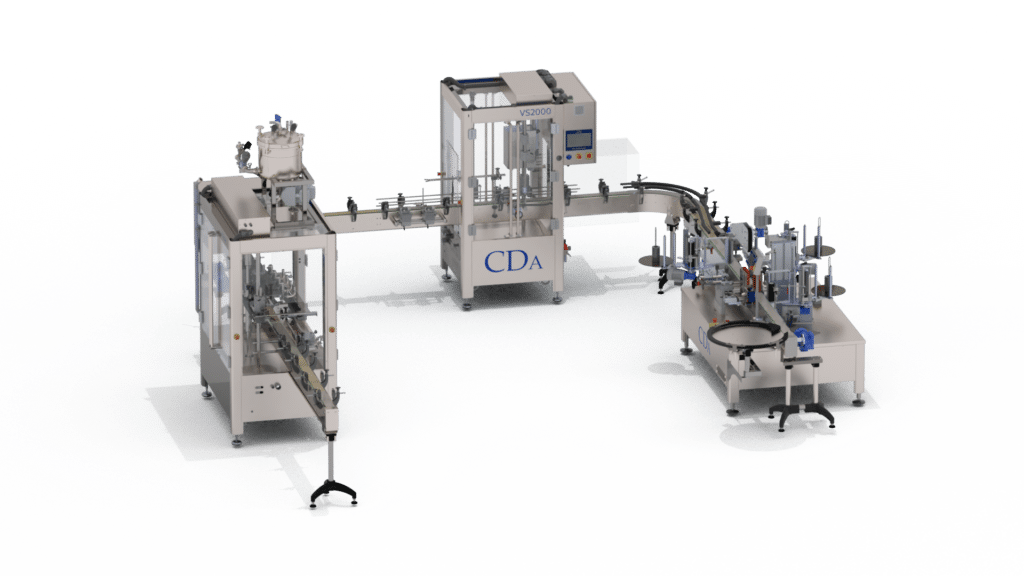

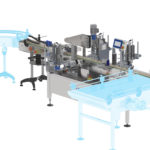

CDA Complete line – K Line S – VS2000 – Ninon Mix Complete automatic line for all products

CDA offers complete solutions that integrate the three essential stages in packaging your products: filling, capping and labelling.

Among our equipment, the K-Line S enclosed linear filler stands out for its ease of use and adjustment. Extremely versatile, this machine is also appreciated for its excellent cleanability. Depending on the nature of your products, we can adapt the dosing system either to measure volume with one or more pistons, or to measure flow, with or without the use of a pressurised buffer tank. With the K-Line S, you can fill up to 3,000 litres per hour while maintaining an accuracy of +/- 0.5% of the dosed volume.

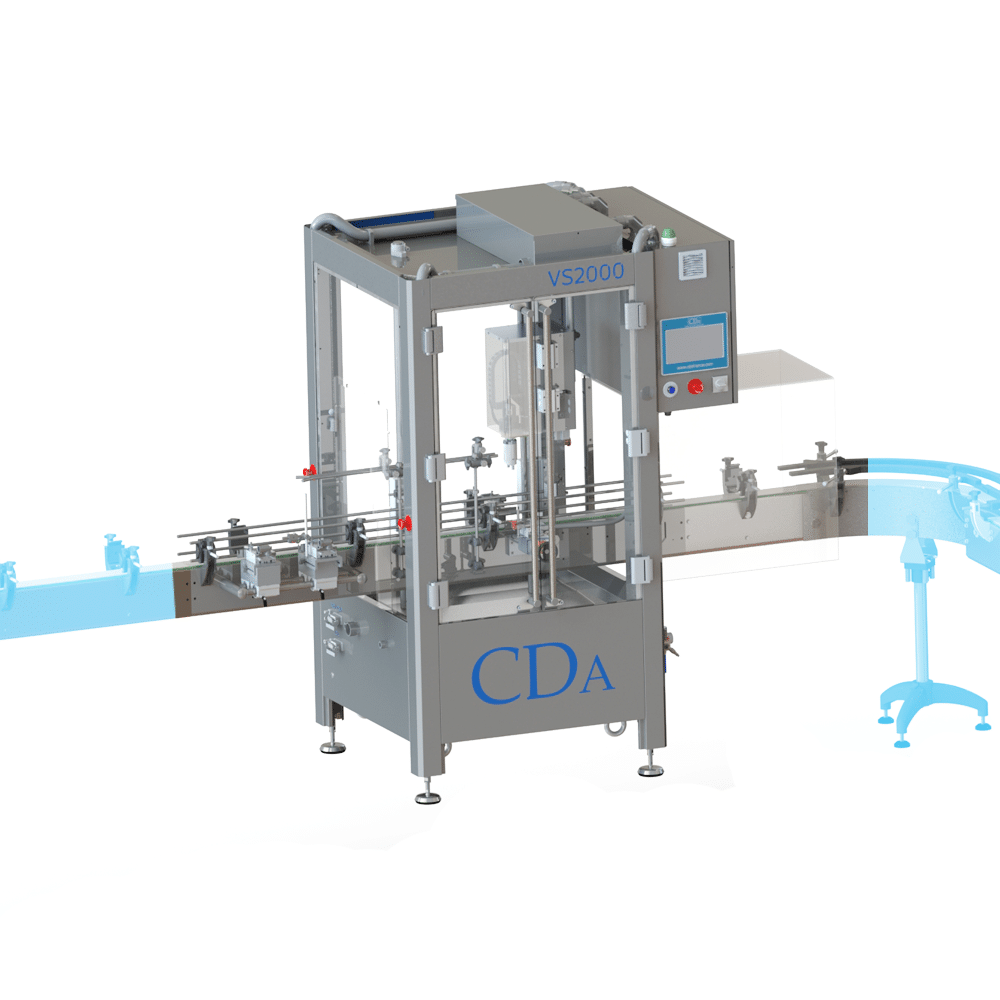

Connected using a linear (or curved/U-shaped, depending on your workshop) conveyor, the VS2000 capping machine automatically feeds and cap a wide range of closures. This capping machine is also fully enclosed for optimum safety. Its capping system, powered by electric screwdrivers, is perfectly suited to spray caps, flat caps, ribbed caps and many more…

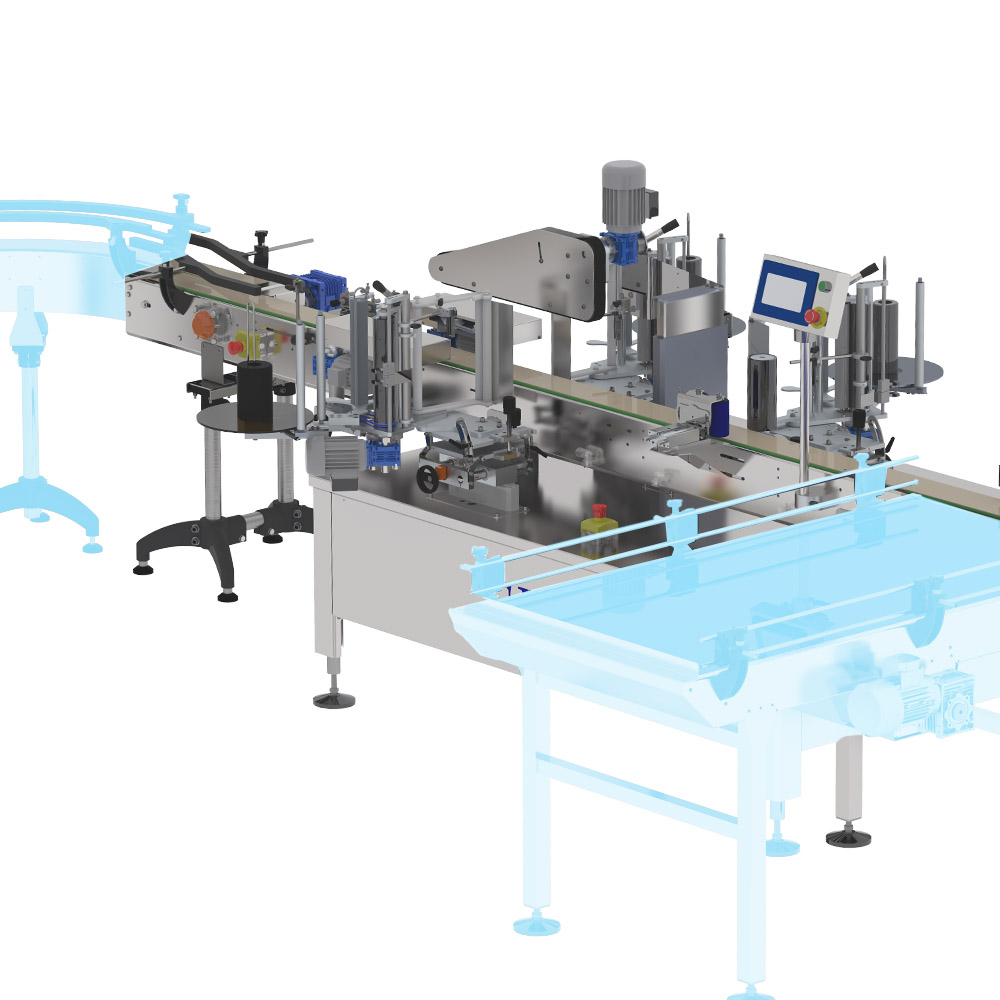

The final stage of the packaging line is handled by the Ninon Mix labeller. This labeller can also be configured for cartoning (on request). The Ninon Mix stands out for its versatility: it can apply up to 5 self-adhesive labels. What’s more, it adapts to a wide variety of product shapes, whether cylindrical, conical, oval or rectangular. This automatic labeller can handle up to 35 products per minute.

To meet your needs as closely as possible, we can integrate complementary solutions into this complete 3-in-1 line. These solutions can include infeed/outfeed tables, marking/coding systems, conveyors and any other element required for packaging your products.

Contact our team of packaging experts to discuss your project!

- Up to 35 products/minute

- Up to 5 labelling stations

- A complete, enclosed line for all products

-

Bottle sizefrom 50 ml to 20L

-

Filling accuracy+/- 0,5%

Cosmetics industry

Food processing industry

Paint industry

Chemical industry

Parapharmacy

Natural products

Car products

Animal products

Container shapes

Heavy

Fluid

Thick

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries