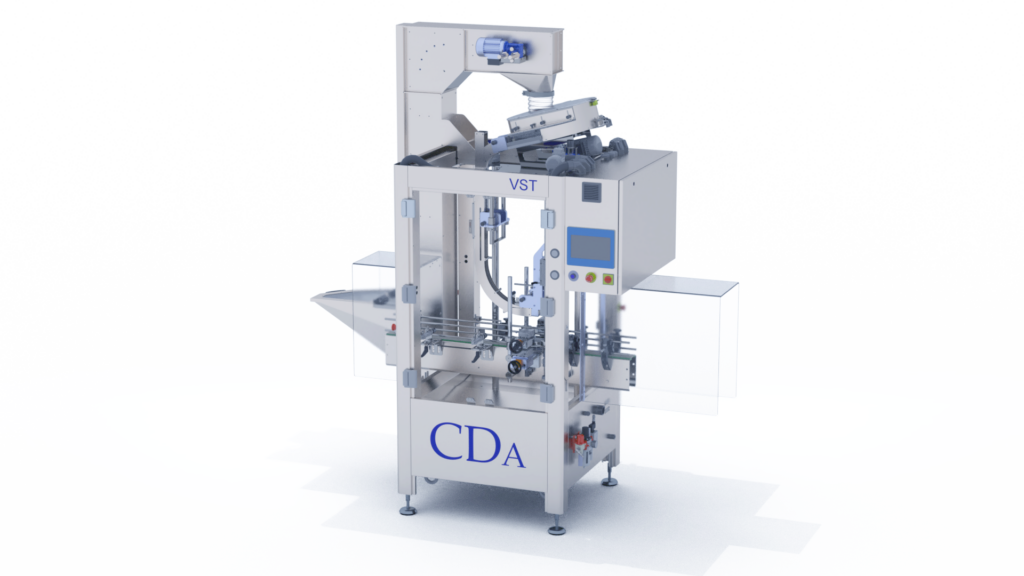

T-cap dispensing and pushing system VST Cap dispensing and pushing machine

The VST is a module for the automatic dispensing and pushing of headed caps. This all-stainless steel linear machine is designed and manufactured by CDA. The VST automatically dispenses T-shaped caps onto the bottles before pushing them in. Its output can reach 1,800 corks/hour (depending on the type of cork, etc.).

The corks are first placed ‘loose‘ in the cap lift hopper. The lift then feeds the corks into an orientation bowl. This then automatically distributes the corks (in the right direction) onto a ramp. It is from this ramp that the corks are automatically distributed to the neck of the bottle. It should be noted that the lift is a ‘standard’ feature, providing greater autonomy and simplifying the operator’s work.

The VST is ideal for the food processing and distillery industries, as it has been specially designed for T corks (usually used in these sectors). The machine is appreciated for its versatility and simplicity of operation and adjustment (such as pushing force).

The VST can be integrated after a CDA linear filler (such as a K-Net Auto or a K-Line S). This machine is also frequently installed before an automatic adhesive labeller (such as a Ninon Mix).

Discover all our videos presenting CDA machines on our YouTube playlist.

Cap / Capsule forms

- Versatility

- Linear machine

- Simple to operate

-

Automatic cork dispensingCustom made to the cork

Food processing industry

Wine - Spirits

Filling, sealing and labelling machines : learn more about the complete packaging lines.

Whatever your sector of activity or your product, CDA puts the experience of its design office at your disposal to develop and design your complete customised line. CDA offers the packaging line perfectly adapted to your needs by adjusting technologies, dimensions, conveyors, etc.

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labelling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries