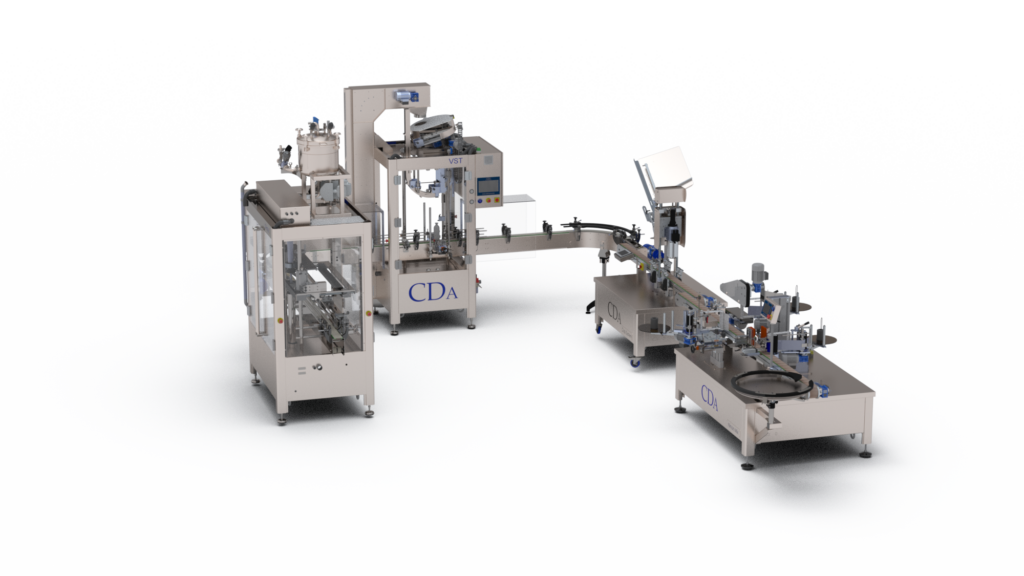

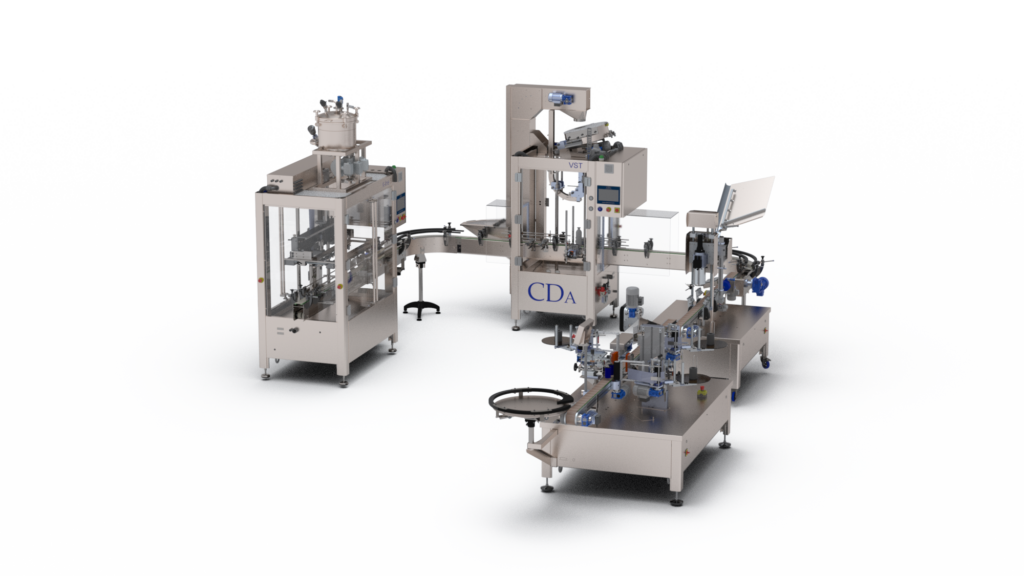

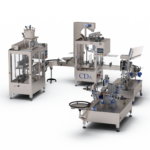

CDA Complete line – K-Line – VST – Cap System – Ninon Mix Complete automatic line for the distillery

CDA offers comprehensive lines (filling, capping, and labelling) perfectly suited for the packaging of spirits. Among our range of solutions, the machines most commonly used in distilleries are as follows:

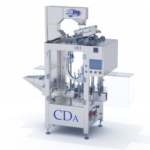

- The K-Line S linear filler. Enclosed, easy to use and adjust, it remains versatile and offers excellent cleanability. Depending on the nature of your products, we adapt the dosing system to meet your needs, whether it’s volume measurement with one or multiple pistons, or flow measurement, with or without the use of a pressurised buffer tank. With the K-Line S, you can package up to 3000 litres per hour, maintaining an accuracy of +/- 0.5% of the dosed volume.

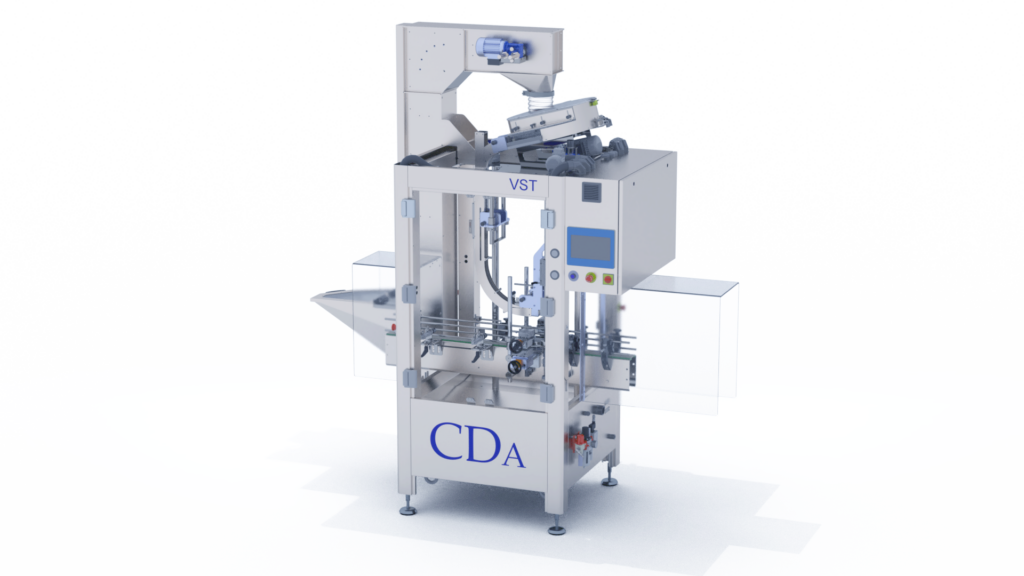

- The VST automatic capper stands out for its versatility and ease of use, offering automatic distribution and capping of T-corks. Equipped with an elevator, it transports the corks to an orientation bowl that distributes them automatically (in the correct direction) onto a ramp. This ramp then ensures the automatic distribution of the corks at the bottle’s neck. The elevator is a standard element, offering greater autonomy and simplifying the operator’s work. With a capacity of up to 1800 corks per hour (depending on the cork type), the VST ensures maximum efficiency.

- The Cap System automatic capper and sealer is ideal for capping/sealing spirits such as rum, whisky, and more. This machine automatically distributes and caps heat shrink capsules and hoods, previously arranged in a “stick” in a hopper. With a capacity of up to 2500 bottles per hour (depending on chosen options, bottle and capsule formats, etc.), it is equipped with a conveyor, a capsule/hood distributor, one or two cappers as needed, as well as an intuitive touchscreen for easy management and setup.

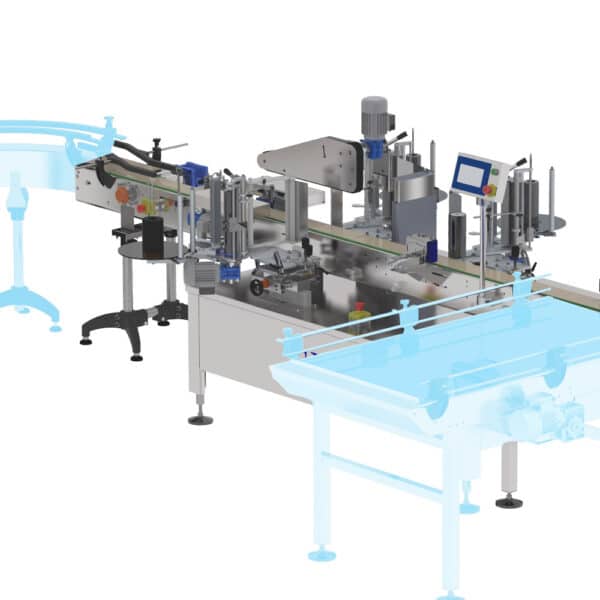

- Finally, the last stage of the packaging line is handled by the Ninon Mix labelling machine. This labeller can also be enclosed (optionally). The Ninon Mix stands out for its great versatility: it adapts to a variety of product shapes, such as cylindrical, conical (tapered), oval, or rectangular. Additionally, this labeller is capable of applying up to 5 self-adhesive labels per bottle.

All of these machines can be connected in various ways to create an L-shaped, U-shaped (or other shapes) line to suit each workshop’s configuration.

To best meet your needs, we offer the possibility of integrating complementary solutions into this line. These may include input/output tables, marking/coding systems, and any other elements necessary for your packaging process.

Feel free to contact our team to discuss your spirits packaging project!

- Up to 2,100 bottles/hour

- Suitable for a wide range of spirits, bottle shapes and labels

- Automatic cap routing

-

Bottle sizesFrom 50 ml to 20L

-

Filling accuracy+/- 0.5% of the dispensed volume

-

LabelsApplication of up to 5 adhesive labels

Wine - Spirits

Container shapes

Fluid

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries