Automatic screwing module VS 600 Automatic screwing module with motorised gripper for all types of corks - VS 600

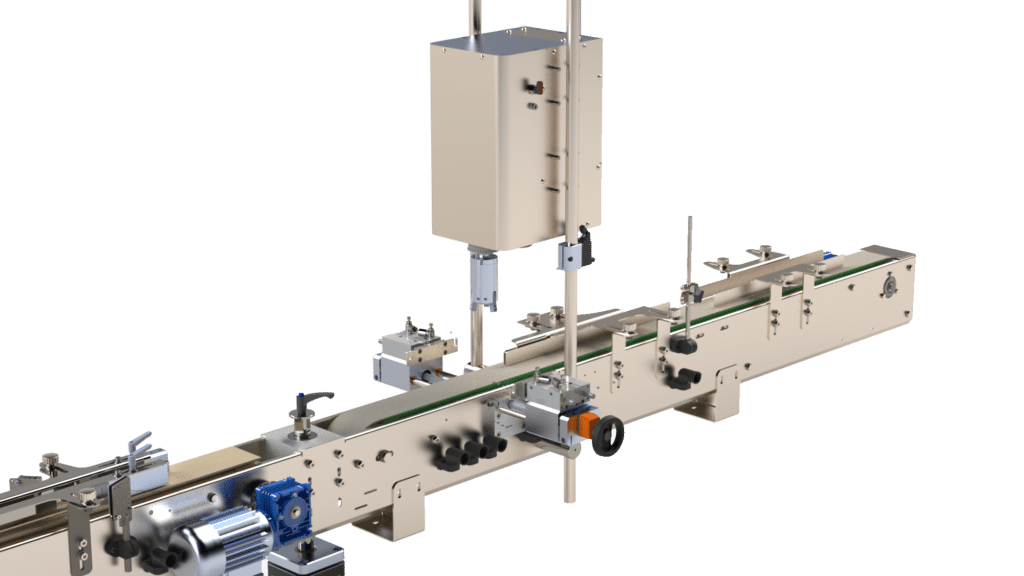

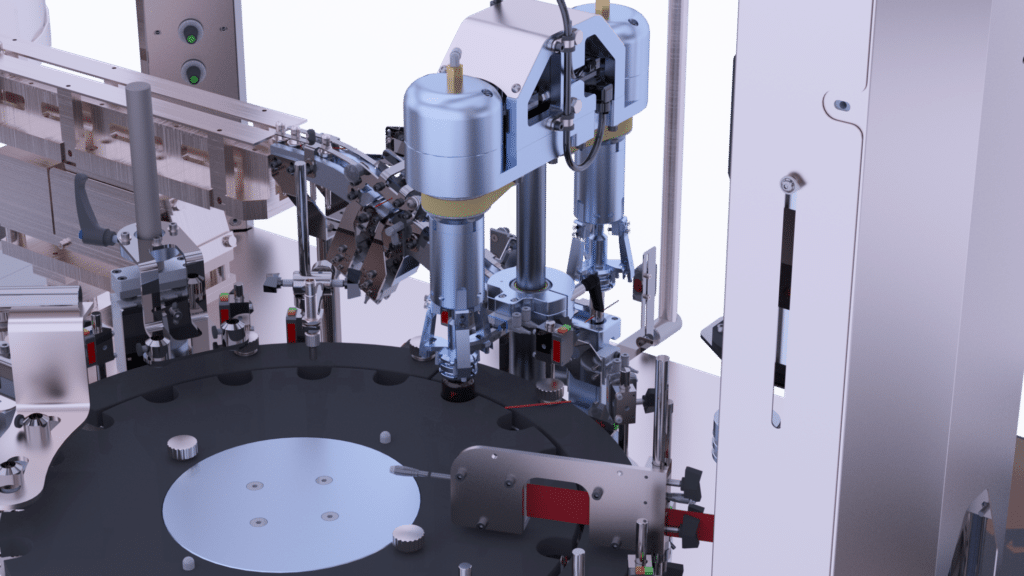

The VS 600 is an automatic screwing module equipped with a motorized clamp driven by a Brushless motor. It can be configured with a screwing head for ribbed caps or a finger clamp for pipette/gun caps. The clamp fingers are made of aluminum alloy (2018).

This screwdriver offers a screwing speed of up to 35 products per minute (depending on the cap, container, applied torque, etc.).

The versatility of the VS 600 is demonstrated by its ability to handle a variety of caps, ranging from 20 mm to 75 mm in diameter. Screwdriving and torque adjustment are performed precisely and reliably thanks to the integrated brushless motor. It’s possible to get feedback on the screwing, adjust the torque directly on the screen, and fully control the settings (rotation/translation), allowing for a wide range of formats to be screwed.

The VS 600 can be optionally integrated into other machines, such as a CDA filler (K-Net Auto, K Line S) or a monobloc (E Fill SW).

With its versatility and screwing precision, the VS 600 meets the needs of a wide range of industries, including food processing, cosmetics, chemistry, animal products, natural products, and many others.

- Screwing head/clamp or venturi system adapted to the cap's format

- Ease of use

-

Screwing1 integrated clamp

-

Screwing speedUp to 35 products per minute, depending on the format

Animal products

Cosmetics industry

Chemical industry

Food processing industry

Filling, sealing and labelling machines : learn more about the complete packaging lines.

Whatever your sector of activity or your product, CDA puts the experience of its design office at your disposal to develop and design your complete customised line. CDA offers the packaging line perfectly adapted to your needs by adjusting technologies, dimensions, conveyors, etc.

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labelling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries