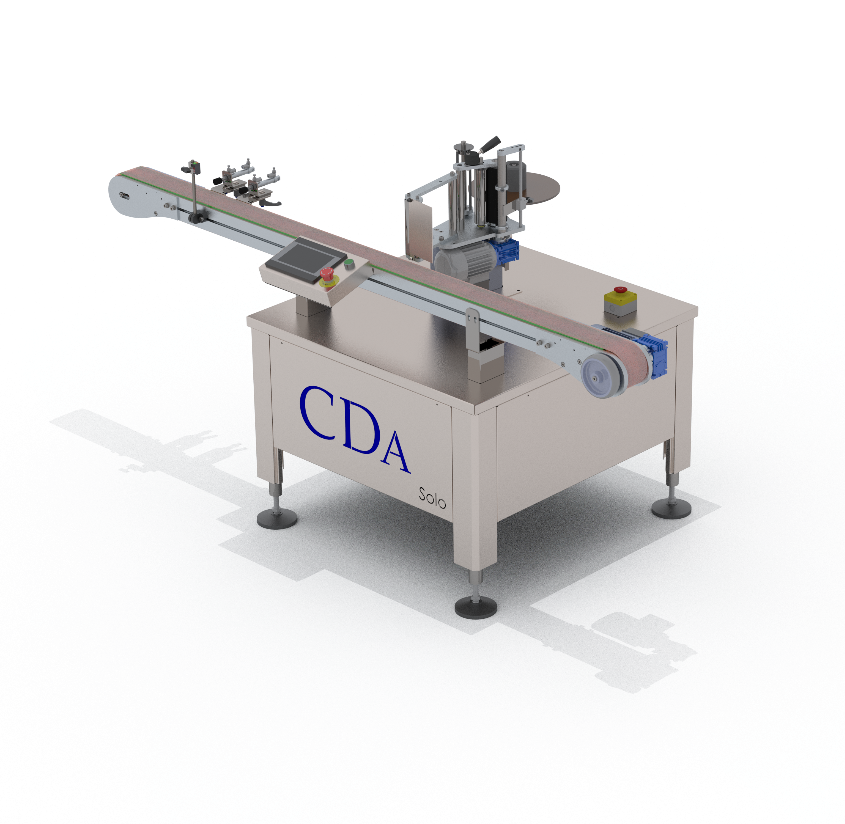

Solo Konic Automatic labelling machine for tapered products

CDA’s Solo Konic is an automatic linear labeller allowing a single pressure sensitive label to be applied onto tapered products. Jars, bottles, cans and tapered buckets are thus covered with a pressure sensitive label with a production rate of up to 20 products / minute (depending on the format of the products and the labels).

This labelling machine adapts to different formats of tapered products in a simple and efficient way, without changing the material.

CDA Solo Konic is used in many industries such as the food industry (jam, olive oil, vinegar), paint (varnish cans, paint buckets) or cosmetics (moisturizer, liquid soap).

This linear automatic labelling machine fits perfectly into a complete packaging line consisting of an automatic filler and a CDA capper. The Solo can also be used independently.

To dispense several labels on the same tapered container, CDA has designed the Ninon Konic.

Discover our labellers on our Youtube channel.

Container shapes

- Ultra-compact size

- Easy to use and adjust

- Excellent value for money

-

Labelling rateUp to 20 products/minute

-

Machine controlVia user-friendly touchscreen

-

Labelling1 label

-

StructureStainless steel and Aluminium

Cosmetics industry

Food processing industry

Paint industry

Beer industry

Chemical industry

Filling, sealing and labelling machines : learn more about the complete packaging lines.

Whatever your sector of activity or your product, CDA puts the experience of its design office at your disposal to develop and design your complete customised line. CDA offers the packaging line perfectly adapted to your needs by adjusting technologies, dimensions, conveyors, etc.

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labelling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries