Founded in 1991 in Narbonne, CDA was born from the desire to provide simple and reliable filling, capping, and labelling solutions to various industries.

Since our inception, we have committed to meeting the specific needs of our clients by providing robust and innovative equipment tailored to their requirements. Over thirty years later, our commitment remains unchanged.

From semi-automatic labellers to complete lines and 3-in-1 monoblocs, we proudly support tens of thousands of companies in their packaging projects.

Today, a new trend is emerging to address environmental challenges: companies aim to maximise their waste valorization. The glassine recycling sector has several collectors and recyclers appearing and offering innovative solutions. For instance, glassine is sometimes transformed into insulation material. However, to facilitate the sorting and recycling of glassine, firstly, it must be stripped of its labels.

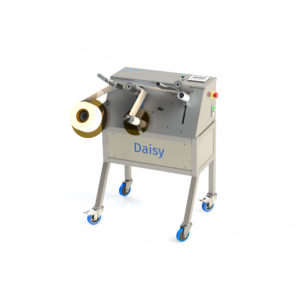

To meet this new challenge, we have developed “Daisy”, the label remover. It offers optimised waste valorization by efficiently separating adhesive labels from their glassine backing. Daisy produces two distinct rolls (one of labels and the other of glassine) to facilitate sorting, collection, and recycling.

Features of the Daisy

Simplified Automatic Operation

Once the tape passes through, a simple push of a button starts the cycle. The labels are peeled from the glassine and deposited onto a cylindrical support. Meanwhile, the glassine is wound separately. Users can choose the material of the core to match the labels (plastic, paper, and more.) for an easier sorting.

High Band Speed

With a band speed reaching up to 60 metres per minute, the Daisy ensures rapid and efficient separation of labels from their backing. At the end of the operation, two compact rolls are created: one of labels and the other of glassine.

Adaptability and Flexibility

Daisy can be customised to meet various needs, whether it is in terms of automation or capacity. Whether you need a multi-station machine, special trays, or other custom configurations, the Daisy can be equipped with different options to perfectly match your requirements.

Why Choose Daisy?

Optimised Waste Valorization

Valorizing your labelling operation waste helps reducing your company’s environmental footprint, as does recycling obsolete label rolls. Stockpiles of unusable rolls can result from several factors, such as outdated legal mentions (due to regulatory changes), marketing changes (like a new logo), or excessive purchases (such as vintage labels that cannot be reused).

Efficiency and Compactness

Thanks to its innovative design and high-speed performance, the Daisy maximises the efficiency and productivity of your label removal operations while ensuring simple operation. Compact and mobile, the Daisy can be easily stored without taking up space in your workshops. Additionally, it only requires a domestic electrical outlet and operates without compressed air or other elements.

Adaptation to Specific Needs

The flexibility of the Daisy allows it to adapt to a wide range of sectors, products, and industrial needs. Whether it is for special configurations or additional options, Daisy can be customised to meet your precise requirements.

CSR Approach

Recycling companies issue a certificate attesting to the quantity of waste collected and recycled. This certificate can be valuable for CSR (Corporate Social Responsibility) initiatives.