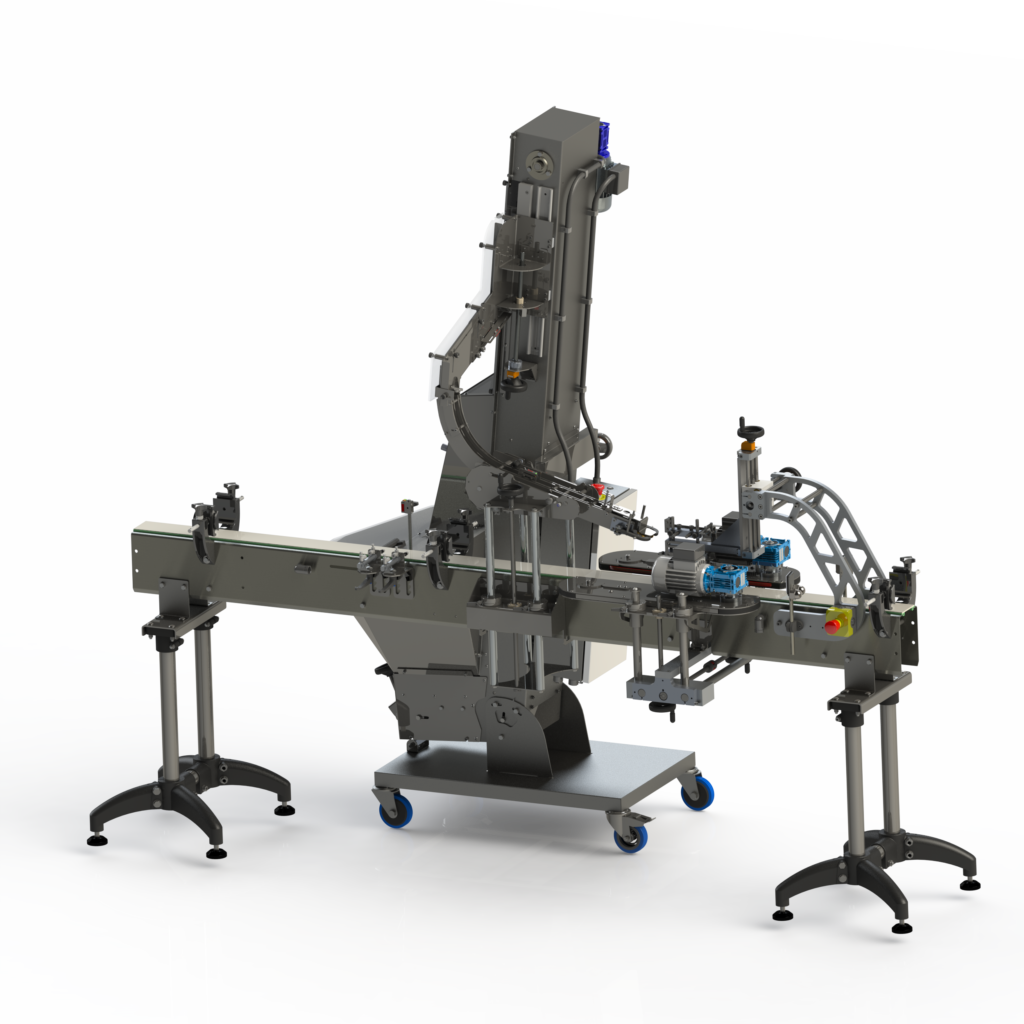

Automatic capsule dispensing DistriCap Automatic lid dispensing & placing machine

The DistriCap is an automatic sorting and distribution module designed and manufactured by CDA. Highly versatile due to its adaptability, it can sort and distribute various types of caps (twist-off with long and/or short skirts) and closures (for cosmetic jars, pill bottles, jerry cans, etc.). This system is compatible with our standalone capping machines, such as the VSA, for continuous cap distribution, or can be used to feed the VS2000, thus enhancing our fully automatic industrial packaging lines by positioning itself between our K-Net Auto or K-Line S fillers and our Solo and Ninon labelling machines.

Equipped with a hopper and an elevating conveyor for cap orientation, it can be fitted with single-format or multi-format ramps depending on the use case, and can also integrate additional controls (such as checking for the presence of an induction seal, for example).

Versatile, reliable, and quiet, the DistriCap is ideal for the food, cosmetics, and many other industries.

Cap / Capsule forms

- Reliability of operation

- Reliability of the capsules drop off onto the containers

-

DistributionAutomatic capsule dispensing

-

CapsulesSuitable for twist off capsules

Cosmetics industry

Food processing industry

Animal products

CBD

Filling, sealing and labelling machines : learn more about the complete packaging lines.

Whatever your sector of activity or your product, CDA puts the experience of its design office at your disposal to develop and design your complete customised line. CDA offers the packaging line perfectly adapted to your needs by adjusting technologies, dimensions, conveyors, etc.

Feed systems (rotary tables, modular conveyor belts, etc.), Conveyor systems, Dosing / filling systems, Capping systems, Labelling systems, End-of-line systems (accumulation, case packing, film-wrapping and palletizing), Marking systems.

LONGEVITY

No planned obsolescence

INSTALLATION

Settled by our team

GUARANTEE/CUSTOMER SERVICE

Our team at your service

EXPERTISE

30 years, 7.000 clients, 105 countries