In a packaging process, performance, quality, and overall line efficiency are the most critical factors for the buyer. To meet these expectations, we have developed innovative solutions tailored to the specific requirements of all industries.

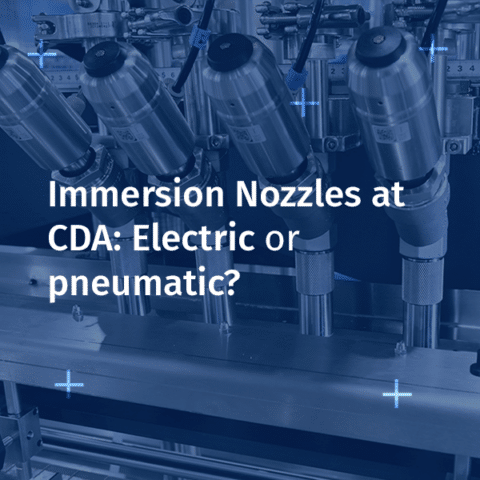

Immersion nozzles: A precise filling system

Immersion nozzles are used to fill containers accurately and quickly. Their design allows them to dip into the neck of bottles and rise during the filling phase. This prevents splashing, bubble formation, and product damage.

An electric system for optimal precision

This system uses fully electric immersion nozzles to provide precise filling control. It is designed for high-speed packaging lines that require maximum accuracy and constant control of the fill volume.

We have developed the K-Line, an automatic filling machine offering precise adjustments of flow rate and immersion depth, ensuring perfect consistency in every filling cycle.

This system is ideal for sensitive or foaming products, where any variation in the filling process could affect the product quality or lead to waste. The ability to precisely adjust the speed and depth of the immersion nozzles also helps optimise energy consumption and reduce operational costs in the long term.

Partial pneumatic system for greater flexibility and adaptability

For certain types of products and line configurations, partial pneumatic systems can offer greater flexibility. Pneumatic immersion nozzles are used in some of our models, such as the K-Net Auto automatic filling machine or the E-FILL and E-FILL SW monoblocks.

These systems combine the efficiency of compressed air with mechanical and electrical technologies, enabling the filling process to be adapted to specific needs while maintaining excellent responsiveness.

Which System to Choose?

The choice between a fully electric system and a partial pneumatic system depends on several factors, including the nature of the product to be filled, production requirements, and the type of containers used.

- Electric System: Ideal for applications requiring ultra-precise control, constant flow regulation, and stable operation. This system is perfect for sensitive products and high-speed lines.

- Partial Pneumatic System: Ideal for applications requiring flexibility and speed, with the ability to manage variations in viscosity or different container formats. This system is best for lines where productivity is essential, and quick, simple adjustments to settings are necessary.

A solution tailored to your needs

We are committed to providing customised solutions for each packaging line. Whether electric or pneumatic, immersion nozzles offer a solution for precise filling, while meeting the technical and economic specifications of each client.

Whether you choose our fully electric K-Line filler or a pneumatic model like the E-FILL, we have the solution to meet your needs.