Since 1991, we have been designing and manufacturing filling, capping, and labelling machines tailored to various industrial sectors (such as veterinary products, essential oils, and para-pharmaceuticals).

Our packaging machines ensure precision, productivity, and flexibility, meeting the specific requirements of many businesses.

In addition to this article, we have created a guide that will help you compare our machines and direct you towards the most suitable equipment for your needs.

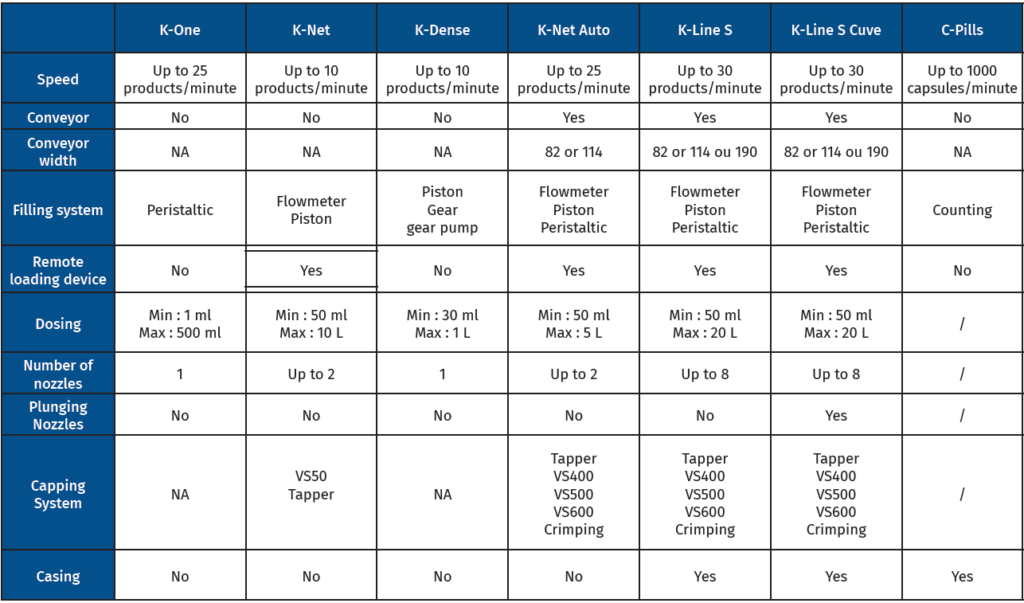

Filling Machines

Our filling machines, whether semi-automatic or automatic, provide precise dosing, easy cleaning, and straightforward adjustments.

Semi-Automatic Fillers

- K-One: Ideal for filling small doses, it is equipped with a peristaltic pump, allowing for a quick changeover between products.

- K-Net: Designed for liquid filling in semi-automatic mode, it features a remote capping system for larger containers.

- C-Pills: Specially designed for counting capsules and tablets, this machine guarantees extreme precision with speeds of up to 1000 capsules per minute.

Automatic Fillers

- K-Dense: Equipped with a gear pump for filling viscous products (such as honey), which are transported via its feeding table.

- K-Net Auto: This automatic filler is ideal for dosing a wide range of products with speeds of up to 1200 units per hour.

- K-Line S: A robust and versatile solution for medium and large-scale production, with speeds of up to 2500 litres per hour.

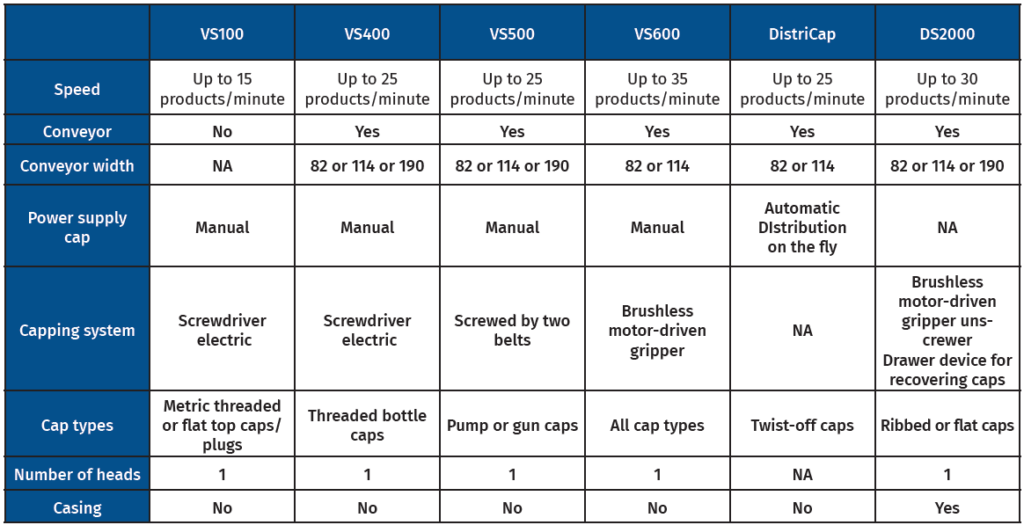

Capping Machines

Semi-Automatic Cappers

- VS 50: This semi-automatic manual capping machine is perfect for small-scale production. It is suitable for both smooth and ribbed caps, offering a simple and effective solution for assisted manual capping.

- VS 100: An autonomous semi-automatic capping machine equipped with a custom capping head. Easy to use with its two-hand control, it allows for precise torque adjustment directly on the head.

Automatic Cappers to integrate with your filler (or labeller)

- VS 400: Designed for cylindrical caps, particularly those with vertical ribs, pipettes, or pre-threaded screw caps. Its custom capping head ensures a perfect fit. The VS 400 can be integrated into various filling machines and achieves speeds of up to 25 products per minute.

- VS 500: Suitable for pump or trigger caps, this capping machine allows for height adjustment via a crank handle.

- VS 600: Featuring a motorised clamp capping head (or a venturi system), it stands out for its ease of use and versatility.

Automatic Capping Machines

- VSA: A versatile automatic capping machine, the VSA can integrate up to two capping systems (VS 400, VS 500, VS 600, or pusher), providing flexibility for different types of caps.

- VS 1000: This capping machine is ideal for pump, trigger caps, and other similar formats.

- VS 2000: An automatic capping machine designed to automatically feed and screw on caps. It handles caps ranging from 20mm to 75mm in diameter.

- DistriCap: This automatic distribution module directs and distributes various types of capsules (twist-off) and caps.

- VST: A system for automatic distribution and insertion of T-shaped caps, ensuring precise and effective placement.

- DS 2000: An automatic unscrewing machine designed to remove caps from various containers, providing an industrial solution for processes requiring unscrewing.

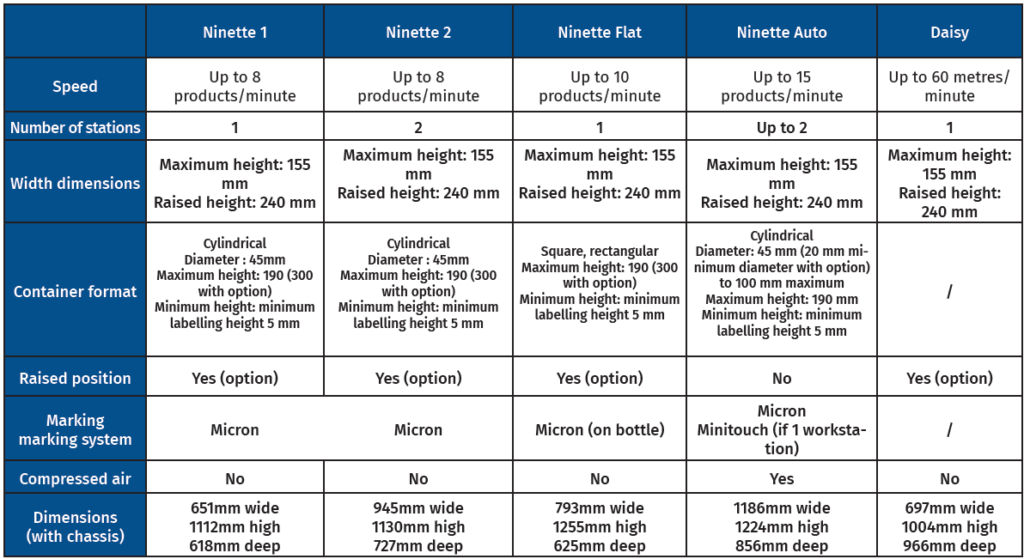

Labelling Machines

Semi-Automatic Labellers – Ninette Range

- Ninette 1: Ideal for semi-automatic labelling of cylindrical containers with speeds of up to 10 products per minute.

- Ninette 2: Designed for applying 2 adhesive labels on cylindrical products in semi-automatic mode.

- Ninette Auto: A semi-automatic adhesive labeller, it also applies 2 labels on cylindrical products with speeds of up to 13 products per minute.

- Ninette Flat: Provides precise and efficient labelling of square, flat, or rectangular products in semi-automatic mode.

- Daisy: A semi-automatic machine designed to separate adhesive labels from their backing, enabling the recycling of glassine.

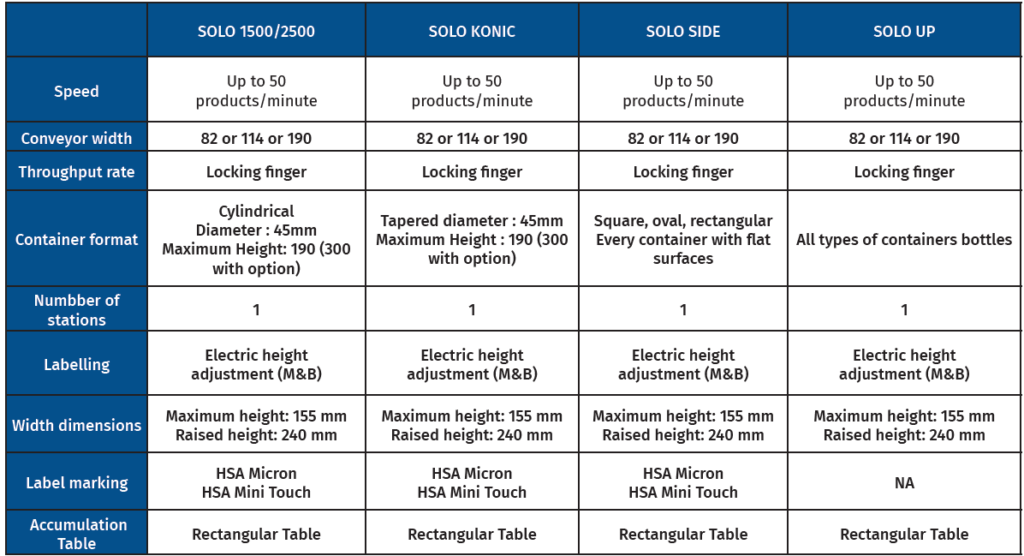

Automatic Labellers – Solo Range

- Solo 1500/2500: Automatically applies 1 label to cylindrical products.

- Solo Konic: Designed for conical containers, it ensures precise label application with speeds of up to 50 products per minute.

- Solo Side: Suitable for flat or rectangular products, it applies labels neatly and consistently to the sides of containers.

- Solo Up: This labeller applies labels to the top of products (ideal for cartons or trays).

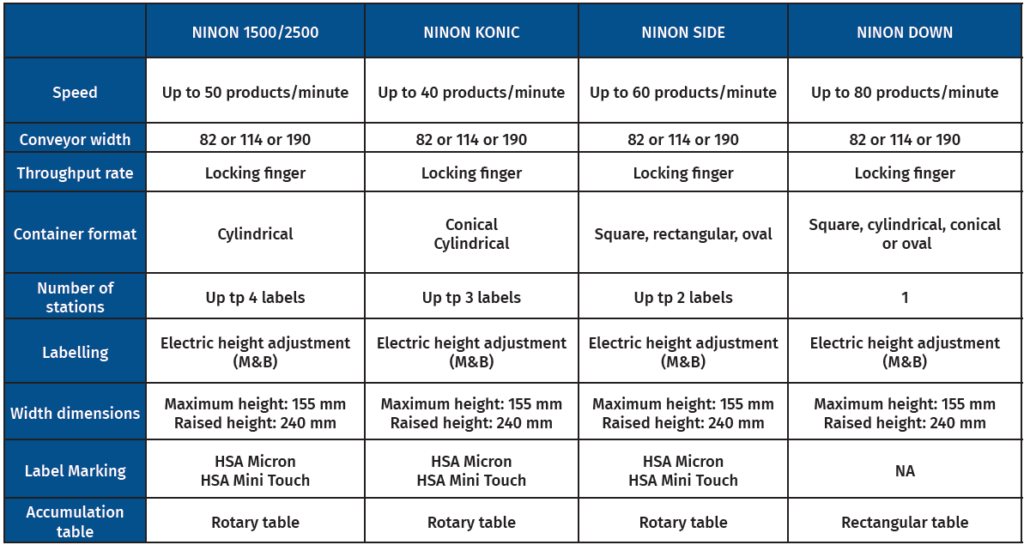

Automatic Labellers – Ninon Range

- Ninon 1500/2500: A machine designed to apply multiple labels to cylindrical products, with speeds of up to 50 products per minute.

- Ninon Side: Designed for labelling the sides of flat or rectangular products with speeds of up to 60 products per minute.

- Ninon Up & Down: Allows for labelling both the top and bottom faces simultaneously, ideal for products of all sizes and shapes.

- Ninon Wrap: Specially designed to apply a wraparound label on cylindrical products, achieving speeds of up to 200 products per minute.

- Ninon By-Pass: Capable of labelling up to 120 products per minute, offering maximum flexibility for various formats.

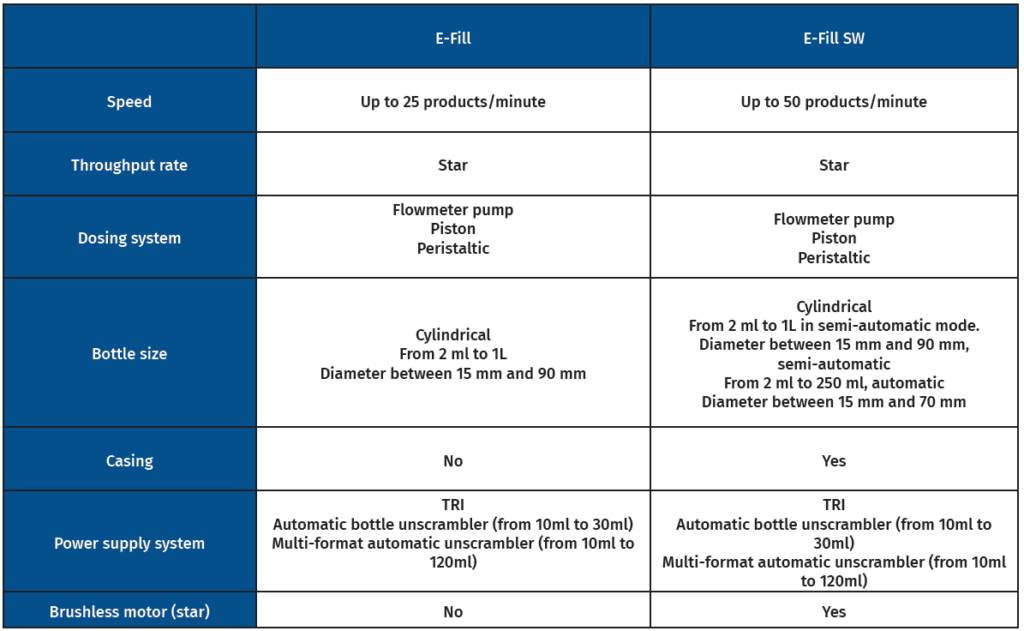

Monoblocks

Monoblock solutions integrate the functions of filling, capping, and labelling into a single compact and efficient piece of equipment, perfect for high-speed packaging lines.

- E-Fill: A 3-in-1 monoblock that performs filling, capping, and labelling for small products at speeds of up to 25 products per minute.

- E-Fill SW: A 3-in-1 machine that also automatically feeds caps onto their containers. Its speed reaches up to 50 products per minute.

Conclusion

We offer a wide range of packaging solutions tailored to your needs in terms of speed, precision, and flexibility. Additionally, we have an R&D department that can provide custom solutions for the most specialised requests. For any requests for quotes or personalised advice, do not hesitate to contact our team.